Sinterex offers the production of the full range of implant restorations using our metal 3D printing technology

Implantology in the dental industry is growing quickly supported by advances in Guided Surgery which provides for more repeatable and accurate results.

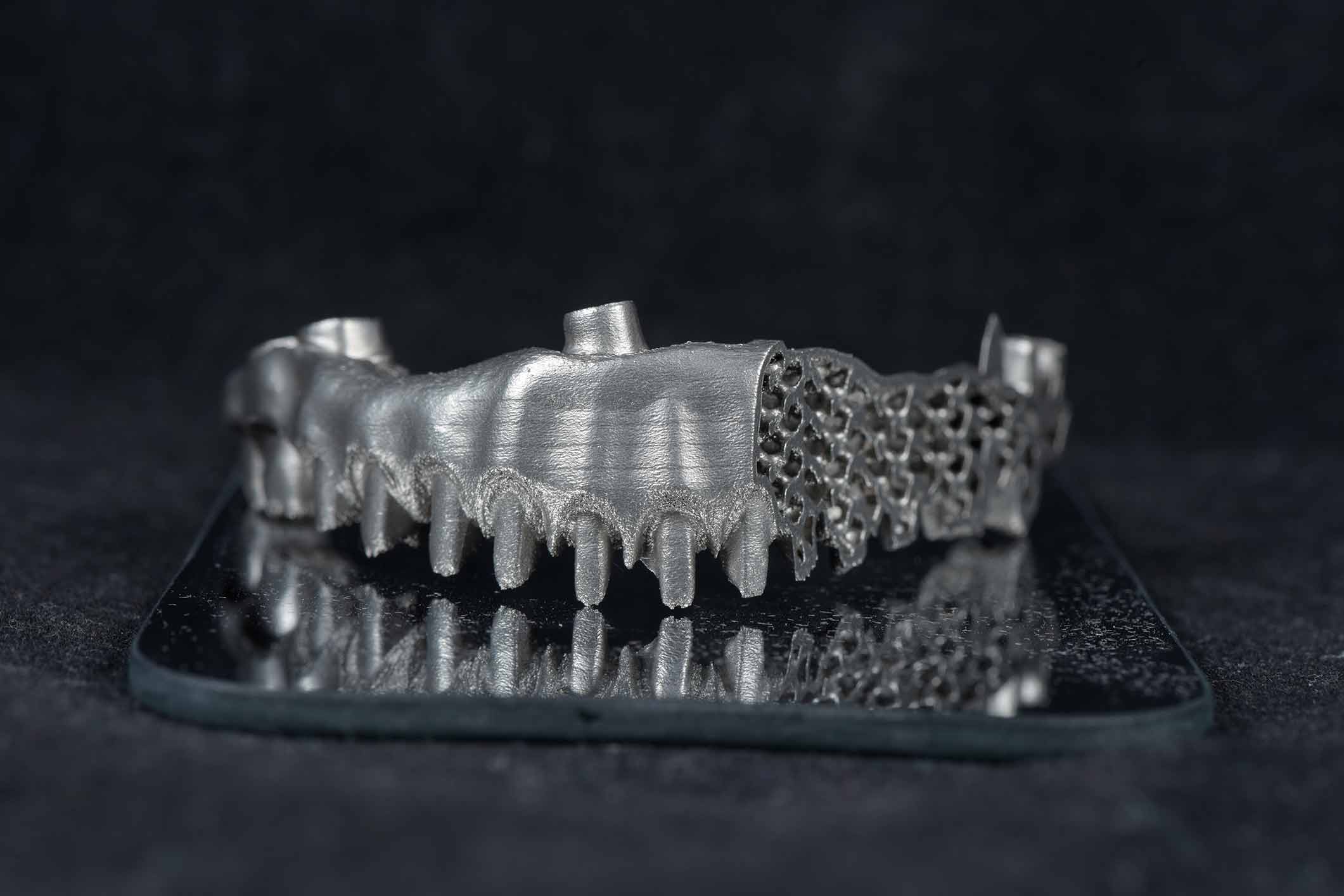

Sinterex offers the production of the full range of implant restorations using our metal 3D printing technology. Using digital design and production technology for implants means that a superior fit is achieved, placing less strain on the implants, leading to better patient outcomes. Furthermore, metal has greater flexibility than Zirconia based frameworks, leading to less chance of cracking on long-span full arch cases.

We can handle all cases, including large complex cases with gingiva. Our high quality bio-compatible material means that soft tissue care is maximised. It is also possible to produce a range of implant bars with bubbles or pins for retention and optimised structures for weight efficiencies.

SPECIFICATION

Metal

All of our PFM restorations are made using a bio-compatible Cobalt Chrome alloy which is FDA approved, EU approved, and also approved by the UAE Ministry of Health.

Performance

The metal conforms to the EN ISO 9693 standard for bonding strength as well as the requirements of EN ISO 7405, EN ISO 10993-1, and EN ISO 10993-5 regarding the biocompatibility of PFM materials.

Compatibility

The mechanical properties of the metal are comparable with a traditional cast metal, giving a CTE of 14.5. As such, our PFM restorations are compatible with nearly all ceramics including Vita, Shofu, GC, Ivoclar, and Geller.